DTF Transfer Size is a foundational consideration in direct-to-film (DTF) printing, shaping how artwork moves from concept to fabric and how it sits on the wearer. When you design garments, the size of the transfer determines how the artwork translates from screen to fabric, how visible it is from a distance, and how durable the result will be after multiple washes, impacting long-term performance. This ultimate guide points designers toward a practical DTF transfer size chart and a clear workflow, while referencing trusted resources like a DTF printing guide and garment sizing guidelines to keep your process consistent. Beyond aesthetics, the right transfer size supports crisp edges, color accuracy, and reliable adhesion across different fabrics and body types, helping ensure comfortable wear, wash durability, and consistent results across sizes. From tees to hoodies to event merchandise, getting the transfer size right remains one of the simplest, most impactful steps to improve consistency and customer satisfaction, reducing returns and building brand trust.

In other terms, the topic can be framed around the printable region on apparel, where designers think in terms of a design footprint that balances visibility with garment fit. LSI-friendly phrasing also considers transfer dimensions, print area margins, and how the artwork interacts with seams, zippers, and fabric texture across different garment types. By using alternative descriptors such as image size, print zone, and center alignment, you reinforce the same concept while expanding relevance for search queries and content understanding. This approach helps content readers connect the idea to practical steps like measuring chest width, margins, and garment-specific layouts, ensuring consistency even when product lines vary.

DTF Transfer Size: Core Principles for Consistent Garment Printing

DTF Transfer Size is a foundational concept in direct-to-film printing, shaping how artwork translates from digital design to fabric. When you plan a collection, the size of the transfer determines legibility, color saturation, and how the print sits on the body. A well-considered transfer size helps ensure crisp edges, accurate reproduction, and reliable adhesion across a range of garments. This subtopic anchors your understanding of how size choices drive consistency and customer satisfaction, and it aligns with practical guidance found in a broader DTF printing guide and related workflow resources.

Beyond aesthetics, the right DTF transfer size balances garment type, print area, and wearer experience. A properly sized transfer avoids crowding seams, necklines, or pockets while remaining visible from a comfortable distance. It also supports durability, since evenly distributed stress reduces edge lift and cracking over multiple washes. Thinking about sizing through the lens of a DTF transfer size chart helps standardize expectations across designers, production teams, and customers, reinforcing a scalable approach to apparel printing.

DTF Transfer Size Chart: Standardizing Print Areas Across Garments

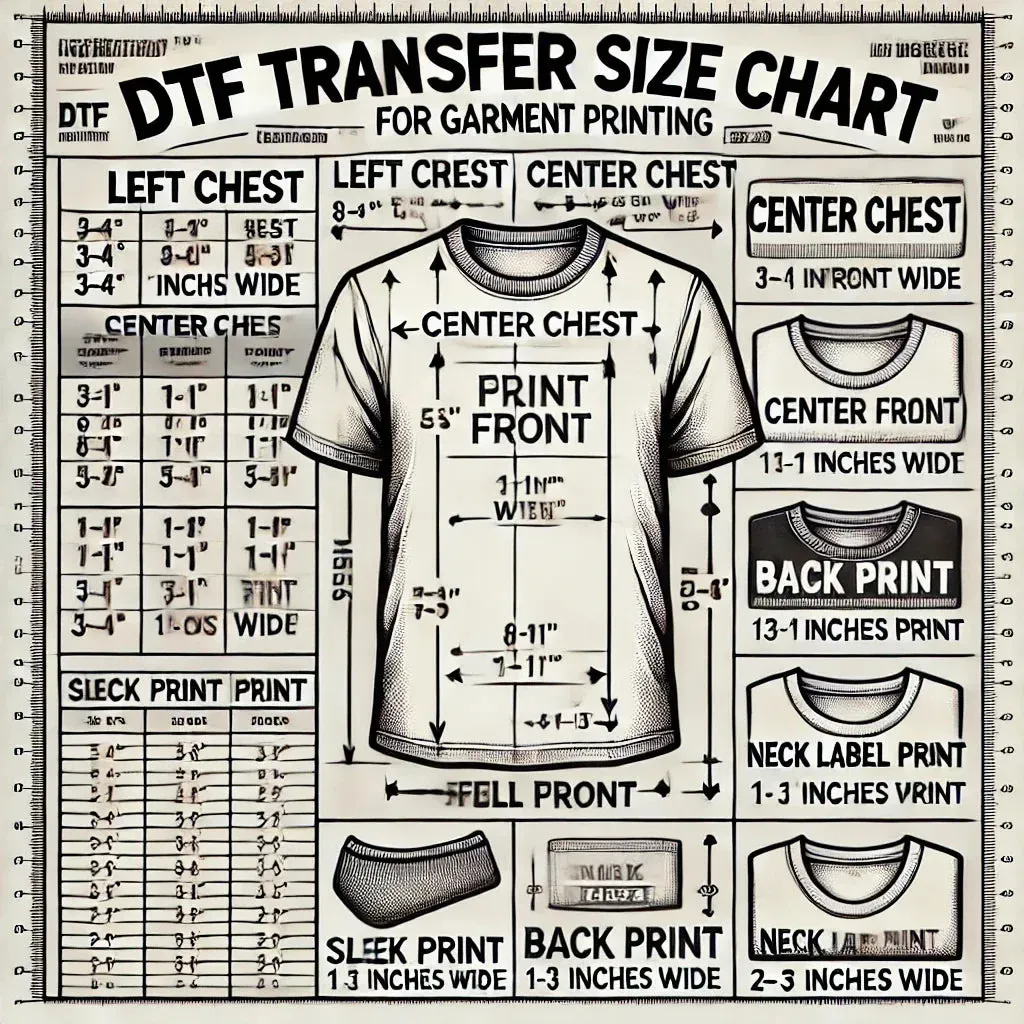

A practical DTF transfer size chart serves as a shared reference to keep artwork proportions consistent across product lines. By mapping common garment sizes (S–XL and beyond) to target width and height measurements, teams avoid guesswork and reduce rework. Integrating a clear transfer size chart into your workflow supports standardization, improves lead times, and aligns with garment sizing guidelines used across brands.

In practice, a well-defined chart informs design decisions from the outset. It guides margins, bleed, and alignment rules so that front chest prints, back designs, or sleeve art maintain proportion on T-shirts, hoodies, or baby garments. As you implement the chart, you’ll notice fewer mid-production adjustments and a smoother handoff between design, prepress, and production, contributing to a more reliable DTF transfer guidelines framework.

Measuring Printable Areas: How to Apply Size Across Garment Types

Measuring the printable area accurately is essential for choosing the right transfer size. Start with key garment dimensions—broad chest width, torso length, shoulder slope—and translate them into a practical print zone. This process mirrors the precision you’d expect from a DTF transfer size chart and mirrors garment sizing guidelines that account for different silhouettes like tees, hoodies, tanks, and baby onesies.

To ensure the design fits across sizes, outline the target area on the garment before printing. Use masking tape or removable markers to capture the intended print zone, then test across multiple sizes and fabrics. By validating measurements in advance, you reduce the risk of edge wrapping or misalignment, which is a common pitfall when scaling artwork without a systematic approach.

Design and File Preparation for Optimal Transfer Size

The file you prepare should reflect the selected transfer size, with a focus on resolution, color accuracy, and margins. Work at 300 DPI or higher (or export high-resolution vectors to raster at the target size) to preserve sharp edges as you resize. Following a DTF printing guide in terms of color space, bleed, and safe zones ensures the artwork remains crisp when applied to garment fabrics.

Clear bleed, safe margins, and proper crop marks are essential for translating design intent to fabric. Convert colors to the preferred color profile for your workflow and maintain scalable artwork that can adapt to various sizes without distortion. By aligning file preparation with transfer size considerations, you minimize surprises during production and improve overall print fidelity.

Common Sizing Pitfalls and How to Avoid Them

Oversized designs can overpower seams and curved surfaces, while undersized prints may fail to deliver the intended impact from a distance. Inconsistent sizing across product lines creates a disjointed customer experience and complicates production planning. These issues are exactly what a robust DTF transfer size chart and standardized processes aim to prevent, aligning teams with clear sizing expectations.

A frequent culprit is not accounting for garment shrinkage or fabric variability. When you neglect shrinkage, a print that looks right fresh off press may appear misaligned after washing. Regular test prints, documented size standards, and ongoing calibration across printers help enforce reliable results and maintain the integrity of your garment sizing guidelines.

Applying Size Decisions: Real-World Scenarios and Frameworks

Scenario-based decisions illustrate how the right transfer size improves outcomes across products. For example, a midweight cotton tee might use a 9–10 inch wide chest print for visibility without crowding the neckline, while a bold back design on a unisex hoodie may use around 12 inches wide to maintain emphasis on both small and large sizes. Such choices align with practical guidelines found in a DTF transfer size chart and DTF transfer guidelines, ensuring consistency across the range.

These scenarios also demonstrate how to balance design intent with fabric constraints, color saturation, and edge fidelity. By referencing the DTF printing guide and garment sizing guidelines, teams can adapt the same sizing framework to a family of products—from youth to adult—while maintaining a cohesive look and dependable wash performance.

Frequently Asked Questions

What is DTF transfer size and why does it matter in DTF printing?

DTF transfer size defines the maximum printable area for a garment transfer. In the DTF printing guide it directly affects visual impact, fit on different body types, and durability after washes. Choosing the right transfer size ensures crisp edges, accurate color, and consistent results across products.

How can I use a DTF transfer size chart to standardize designs across garment sizing guidelines?

A DTF transfer size chart translates design dimensions into standard widths and heights for each garment size (S–XXL). By associating each size with specific measurements, you maintain consistency in front chest and back prints, respect margins, and align with garment sizing guidelines for a reliable workflow.

What are recommended DTF transfer sizes for common garments according to a DTF printing guide?

For adult T-shirts, a chest print often ranges from 9–11 inches wide and 9–10 inches tall; larger or bold designs may be 11–13 inches wide. Hoodies commonly use 11–13 inches wide by 11–13 inches tall. Refer to the DTF printing guide and garment sizing guidelines for precise adjustments per fabric and size.

How do you measure and set the right DTF transfer size on each garment?

Follow a simple process: determine target print area on flat garments, reference your DTF transfer size chart for standard sizes, choose width first then height, add 0.5–1 inch margins, and validate with test prints. This workflow aligns with DTF transfer guidelines to ensure consistent results.

What role do margins, bleed, and safe zones play in DTF transfer size decisions?

Margins (0.5–1 inch) and safe zones prevent edge wrapping and misalignment, especially on seams or curves. Bleed areas should translate to printable margins in the transfer file. Following DTF transfer guidelines helps protect critical artwork and maintain clean edges.

How can I maintain consistency in DTF transfer sizes across product lines?

Develop and document a standard DTF transfer size chart for all products, train teams to measure printable areas consistently, and review designs against the chart before printing. Using garment sizing guidelines alongside the DTF transfer size chart ensures uniform results across styles.

| Aspect | Key Points |

|---|---|

| What is DTF transfer size | – Defines the maximum printable area for a single garment transfer and the design’s dimensions before application. – DT F transfers can be sized to fit different garments (tees, hoodies, baby onesies, etc.). – Proper size ensures crisp edges, color accuracy, and appropriate adhesion, avoiding crowding or misalignment. |

| Why size matters in DTF printing | – Visual impact: affects legibility, color density, and perceived quality. – Garment type: different silhouettes have different printable areas (tees vs. tanks vs. baby garments). – Wearer experience: ensures the print sits well across sizes and body shapes. – Durability: properly sized transfers distribute stress and reduce edge cracking or peeling. |

| Key factors to determine the right DTF transfer size | – Garment dimensions and printable area: measure chest width and torso length; typical ranges: tees 9–11 inches wide; hoodies 11–13 inches; adjust for size (S–XXL). – Artwork margins: consider center, left chest, or back placement; safe margin 0.5–1 inch. – End-user expectations and garment category: standardize sizes with a DTF transfer size chart. – Substrate variety: fabric color/texture can affect perceived size; adjust for dark vs light fabrics. – Printer/heat-press capabilities: larger transfers may need bigger platens and careful dwell times. |

| How to measure and set the right DTF transfer size (step-by-step) | 1) Determine target print area on each garment: lay flat and outline print area, accounting for seams/pockets. 2) Reference a size chart: map sizes (S, M, L, XL) to specific width/height. 3) Decide on width first, then height: start 9–11 inches wide for chest prints on tees; adjust to preserve aspect ratio. 4) Include margins and bleed: add 0.5–1 inch around artwork. 5) Validate with samples: test on different body shapes/fabrics and refine. 6) Document the standard: create guidelines for production teams, designers, and customers. |

| DTF transfer size chart: a practical starting point | – T-shirt (adult): • Small–Medium design: 9–10 in wide × 9–10 in tall • Large/bold design: 11–13 in wide × 9–11 in tall – T-shirt (XL+): 11–13 in wide × 10–12 in tall – Hoodies: 11–13 in wide × 11–13 in tall – Ladies’/fitted tees: 8.5–9.5 in wide (similar height) – Tank tops/junior sizes: 6–8 in wide (small) or 7–9 in wide (medium) Note: adapt to brand standards and equipment; consistency is key. |

| Design considerations and optimization for the right size | – Maintain aspect ratio; center and align with body landmarks depending on front/back design. – Color saturation and edge fidelity: larger prints may require deeper color and careful previewing to avoid banding. – Material color considerations: darker fabrics may need slightly larger prints with under-base for opacity; lighter fabrics can be more conservative. |

| File preparation for the right size in DTF transfers | – Resolution: 300 DPI or higher; vector-originated designs should export high-res raster at target size. – Color space: use Adobe RGB or sRGB; convert to the appropriate profile before printing. – Bleed and crop marks: include bleed if required. – Safe zones: build margins to protect critical elements from edge misalignment. |

| Practical tips for consistent results | – Test prints across garment sizes/colors before large runs. – Standardize measurements across departments to prevent drift. – Account for shrinkage and post-wash changes when changing fabrics. – Monitor production variations and calibrate multiple machines for consistency. |

| Common mistakes to avoid when choosing DTF transfer size | – Oversizing: can cause distortion, seam issues, and alignment problems on curves. – Undersizing: weaker visual impact and reduced legibility on larger garments. – Inconsistent sizing across products without a standardized chart. – Ignoring shrinkage: misalignment after washing. |

| Real-world scenarios illustrating DTF transfer size decisions | – Scenario 1: 9–10 inch chest print on midweight cotton tee for family events remains visible without crowding. – Scenario 2: 12×11 inch back print on unisex hoodie creates a focal point that stays legible on different sizes. – Scenario 3: Junior line uses 7–8 inch prints with proportional height to fit smaller torsos. |

| Comparing DTF transfer sizing with other methods | – DTF advantages: flexible sizing, high color fidelity, adaptable to many fabrics. – When to consider alternatives: high-volume runs with tiny details may benefit from adjusted transfer dimensions to preserve clarity. |

| Conclusion: Mastering DTF transfer size for consistency and impact | In mastering DTF transfer size, you balance design intent, fabric constraints, and production practicality to deliver consistent, high-quality prints across products and sizes. Establishing a DTF transfer size chart, measuring printable areas on each garment, and validating results with test prints will improve color, sharpness, and alignment across runs. Small adjustments in width, margins, or height can significantly enhance perceived value and wash durability. By following these guidelines, you’ll build trust with customers who expect reliable, repeatable results from your brand. |

Summary

Conclusion: Mastering DTF transfer size for consistency and impact

In mastering DTF transfer size, you balance design intent, fabric constraints, and production practicality to deliver consistent, high-quality prints across products and sizes. Establishing a DTF transfer size chart, measuring printable areas on each garment, and validating results with test prints will improve color, sharpness, and alignment across runs. Small adjustments in width, margins, or height can significantly enhance perceived value and wash durability. By following these guidelines, you’ll build trust with customers who expect reliable, repeatable results from your brand.