UV DTF transfer is redefining garment decoration with fast curing, bold color, and broad fabric compatibility. As brands seek quicker turnarounds, a comparison of UV DTF transfer to UV DTF vs traditional methods reveals where speed, cost, and durability matter most. This guide outlines the DTF transfer pros and cons across common materials and production scenarios. Key performance factors, including UV DTF durability and adhesion, help determine which path delivers lasting prints on cotton, blends, and synthetics. Understanding DTF transfer performance across substrates and workflows lets you choose the approach that best fits your brand’s needs.

From a different angle, these UV-curable prints on film are often described as UV-curable DTF transfers, blending digital artistry with fabric-friendly adhesion. LSI-friendly terms you’ll encounter include UV-ink on film, UV printing on textiles, and film-to-fabric transfer, all pointing to the same core process. Other related phrases such as UV-curable pigment film, UV-assisted image transfer, and light-cured DTF help connect this technology to broader topics like textile decoration and production workflows. Recognizing these alternative terms supports content discovery around substrate versatility, color fidelity, and rapid production cycles. In practice, the goal remains the same: a vibrant, durable print that adheres well across diverse fabrics with a streamlined workflow.

UV DTF Transfer Fundamentals: What It Is and How It Works

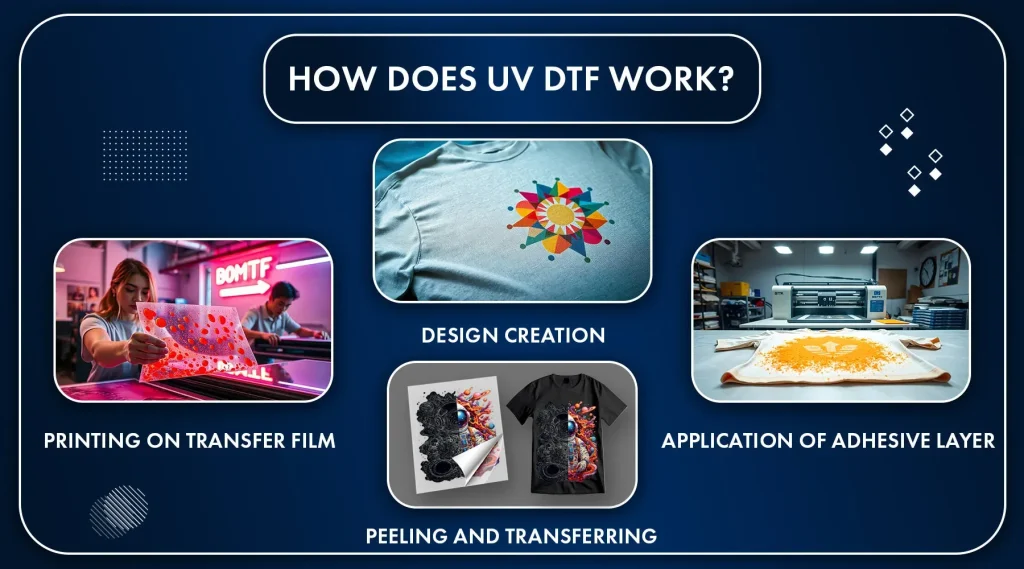

UV DTF transfer combines Direct-to-Film printing with UV-curable inks that fix instantly after exposure, enabling a transfer that can be handled quickly and moved to the finishing stage sooner. The core idea is to print onto a special transfer film, cure with UV light, and apply heat and pressure to move the image onto cotton, blends, and select synthetics. This approach leverages the benefits of UV curing—room-temperature processing and rapid fixation—while maintaining the color fidelity and detail associated with DTF workflows.

In practice, the UV DTF transfer workflow focuses on a streamlined sequence: print on film, UV cure, align, and press. The result can shorten drying times and reduce overall lead times, making it attractive for on-demand printing. When evaluating DTF transfer performance, designers look at edge sharpness, adhesion, and substrate compatibility across a broad fabric range.

UV DTF Transfer vs Traditional Methods: A Side-by-Side Comparison

Placing UV DTF transfer beside traditional methods—screen printing, heat transfer vinyl (HTV), sublimation, and conventional DTF—highlights distinct trade-offs in color density, durability, and throughput. The UV approach blends the color vibrancy of DTF with the efficiency of UV curing, offering a different balance than traditional routes. This is a core element of the UV DTF vs traditional methods discussion and essential for decision-making in production environments.

Screen printing excels in large runs and punchy economy but can be slower for small batches. HTV provides rapid proofs yet may yield varying hand feel and durability across fabrics. UV DTF transfer aims to improve on these aspects by supporting robust color, fine detail, and broader fabric versatility, which reflects the ongoing evolution of DTF transfer performance in real-world applications.

DTF Transfer Pros and Cons: What You Gain and What You Trade Off

DTF transfer pros and cons center on speed, color quality, and substrate reach. Quick cure times with UV-inspired processes can shorten production cycles, while the vivid color gamut and sharp detail support high-fidelity reproductions. The combination of film-based printing and adhesive transfer broadens substrate compatibility, extending the range from cotton to blends and some synthetics.

On the downside, upfront capital for UV DTF systems, film, and curing hardware can be significant. Some fabrics may feel stiffer after heavier ink loads, and precise process control is necessary to avoid color shifts or adhesion issues. Weighing these factors against long-term durability and ecosystem maturity is key to evaluating DTF transfer performance and total cost of ownership.

UV DTF Durability: Wash Resistance, Flexibility, and Long-Term Performance

UV DTF durability is a major selling point when the ink is properly cured and finished. UV-curable inks, combined with a solid film adhesive, can deliver reliable wash resistance and resistance to cracking on many common fabrics. Durability testing against typical care cycles helps quantify how well a design holds up in real-world use.

However, long-term durability varies with fabric type, care patterns, and cure parameters. For premium jobs, testing across multiple washes and abrasion scenarios helps validate expectations and informs care instructions. Ultimately, UV DTF durability hinges on controlled curing, appropriate substrate preparation, and ongoing process optimization.

DTF Transfer Performance Across Fabrics and Substrates

DTF transfer performance across fabrics is influenced by fiber content, weave, and pretreatment. Cotton, poly blends, and synthetics respond differently to ink load and film adhesion, so drivers like adhesion strength, edge fidelity, and color density matter for overall results. This variation highlights why factory testing on target fabrics is essential in the DTF transfer workflow.

Comparing performance across fabrics reveals how UV DTF and traditional DTF behave differently on poly blends versus 100% cotton. The choice of primer, adhesive layer, and curing parameters shapes durability, wash resistance, and the ability to reproduce fine details and color gradients with consistent quality.

Choosing UV DTF Transfer: When to Pick It Over Traditional Methods

Choosing UV DTF transfer comes into play for on-demand apparel, fast proofs, and designs requiring complex color gradients. The method supports a broad substrate strategy, enabling a single process to cover cotton, blends, and select synthetics while maintaining high color fidelity and crisp edges. This makes it a strong candidate for brands prioritizing speed without sacrificing print quality.

To decide, run controlled samples comparing UV DTF transfer to traditional methods such as screen printing or HTV. Build a line-by-line cost analysis, including capital expenditure, ink and film consumption, and maintenance. A structured evaluation of DTF transfer performance on your most-used fabrics will help determine if UV DTF transfer is the right path for your product line.

Frequently Asked Questions

How does UV DTF transfer compare to traditional methods (UV DTF vs traditional methods) in terms of speed, color, and durability?

UV DTF transfer often cures instantly with UV light, delivering fast turnaround and vibrant color on a wide range of fabrics. Compared with traditional methods like heat transfer and screen printing, it can reduce drying time and bottlenecks, though equipment costs and ongoing maintenance can impact total cost of ownership, especially at low volumes.

DTF transfer pros and cons: where does UV DTF transfer fit?

Pros include quick cure, strong color vibrancy, broad substrate compatibility, and potentially solid wash durability when cured properly. Cons involve higher upfront equipment costs, potential stiffness on heavier ink loads, more complex maintenance, and a less mature ecosystem of films and inks in some markets.

What factors affect UV DTF durability across fabrics?

Durability depends on achieving complete curing, the fabric type, pretreatment, and finishing steps. UV DTF durability is generally strong on cotton and blends when cured correctly, while some synthetics may require primers or adjusted formulations for optimal longevity.

DTF transfer performance on different fabrics with UV DTF transfer

DTF transfer performance on different fabrics is strong for cotton and blends, with sharp edges and faithful color fidelity when cured parameters are optimized. Some synthetics may need pretreatment or cure adjustments to maximize adhesion and wash resistance.

What factors influence DTF transfer performance when using UV DTF transfer?

Key factors include color gamut and edge fidelity, adhesion between ink, film adhesive, and fabric, and curing parameters such as lamp intensity and exposure time. Fabric texture and proper calibration are also critical, so run targeted tests on your target materials.

When should you choose UV DTF transfer over traditional methods?

Choose UV DTF transfer when you need fast proofs, on-demand printing, and a broad substrate strategy across cotton, blends, and some synthetics. For very large-volume runs or simple one- or two-color designs, traditional methods or standard DTF may be more cost-effective due to equipment and ink usage.

| Aspect | |

|---|---|

| What is UV DTF transfer? | UV-curable Direct-to-Film printing uses UV inks on a specially prepared film. The design is cured with UV light, fixing the ink on the film. It is then transferred to a substrate using heat and pressure. The UV cure provides rapid handling times with vivid color and sharp detail, and the process works well on cotton, blends, and some poly fabrics. |

| How UV DTF transfer stacks up against traditional methods | Compared to methods like screen printing, HTV, sublimation, and traditional DTF, UV DTF aims to combine color fidelity and durability with faster curing. It can reduce drying time bottlenecks and work across a broader substrate range, but upfront costs, material availability, and long-term durability can vary by application. |

| Pros of UV DTF transfer | 1) Quick cure and production speed: UV curing fixes ink immediately, shortening the production cycle. 2) Color vibrancy and detail: wide color gamut with crisp edges and high detail. 3) Substrate versatility: bonds well to cotton, blends, and some synthetics. 4) Print reliability and wash performance: good durability when properly cured. 5) Environmental/process factors: can reduce solvent exposure and drying times in some shops. |

| Cons and considerations of UV DTF transfer | 1) Upfront equipment and operating costs. 2) Material compatibility and feel: some fabrics may feel stiffer with heavier ink loads. 3) Process optimization and maintenance: requires monitoring of lamp intensity and exposure. 4) Availability and ecosystem: variability in films, primers, and inks by supplier. 5) Long-term durability under extreme conditions: validation needed for top-tier applications. |

| Performance factors to consider when evaluating UV DTF transfer | Color gamut and edge quality: relies on ink and curing calibration for crisp edges. Adhesion and fabric compatibility: different fabrics respond differently and may need pretreatments. Durability and wash performance: perform wash tests on target fabrics. Flexibility and workflow: balance small runs vs. production throughput and UV curing capacity. Cost-per-unit and scalability: economics shift with volume due to ink, film, and maintenance. Quality control and training: standardized curing and operator training are essential. |

| Use cases and decision guide: when to choose UV DTF transfer versus traditional methods | – On-demand apparel and rapid proofs: faster lead times than many traditional methods. – Complex, multi-color designs: strong fidelity for photos/artwork. – Broad substrate strategy: works across cotton, blends, and some synthetics. – Budgeting considerations: capital costs may be a constraint for low volumes. – Quality and longevity requirements: validate durability for your target market. |

Summary

Table summarizes key points about UV DTF transfer, including what it is, how it compares to traditional methods, pros and cons, performance considerations, use cases, and decision guidance.